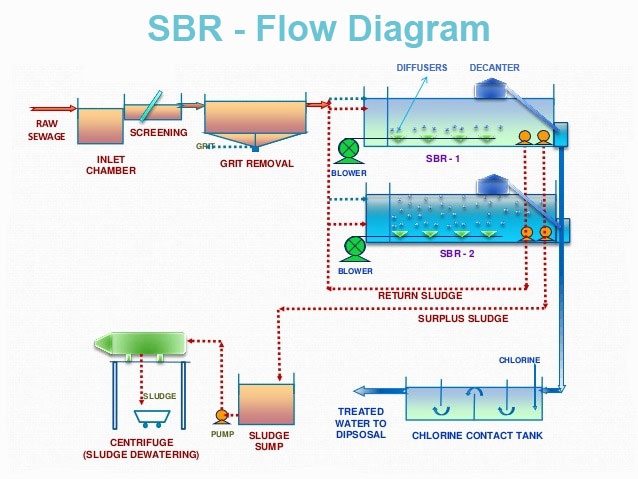

The SBR's Cleansing Symphony:

Filling Up: The journey begins with the tank filling up with influent wastewater – raw, untreated water in need of purification. Picture murky, nutrient-rich water entering the tank, ready for its makeover.

SBR tank being filled with influent wastewater

The Aerobic Feast: Buckle up for the main event! In the aeration/reaction phase, air bubbles dance through the water, creating a bubbly haven for microscopic heroes – microorganisms. These tiny marvels, fueled by the oxygen, feast on organic pollutants, breaking them down and transforming them into harmless byproducts. Imagine billions of miniature chefs whipping up a delicious (for them) and clean (for us) concoction.

SBR tank with aeration bubbles and microorganisms

Time to Settle: After the energetic feast comes a period of peace. The aeration stops, and the tank enters the settling phase. Picture the water calming down, allowing solid particles and the activated sludge, now laden with processed pollutants, to gracefully sink to the bottom. Think of it as the confetti settling after a vibrant celebration.

Crystal Clear Decanting: Now for the grand reveal! The decanting phase carefully siphons off the effluent, the crystal-clear water that has been purified by the microbial feast. Imagine sparkling, clean water flowing out of the tank, ready for further treatment or safe discharge.

SBR tank decanting the clarified effluent

Sludge Shuffle: But wait, there's more! The remaining sludge at the bottom isn't waste – it's a treasure trove of microorganisms. This valuable resource is retained for the next cycle, ensuring a ready-made crew for the next round of wastewater transformation. Think of it as saving the best dancers for the next party.

Tank Refresh: Finally, the tank takes a breather in the idle phase. Any remaining liquid is drained, and the system preps for a fresh batch. Picture the stage being reset, ready for the next wastewater waltz.

This cyclical dance of filling, aerating, settling, decanting, and idling makes the SBR system incredibly versatile. It can handle fluctuating wastewater flows and varying pollution levels with ease, making it a popular choice for small to medium-sized treatment plants.

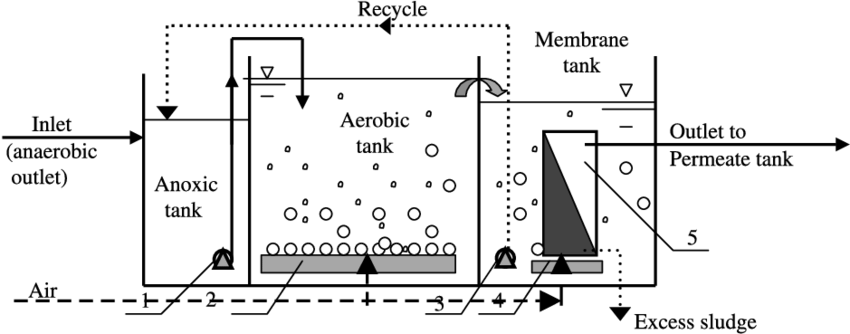

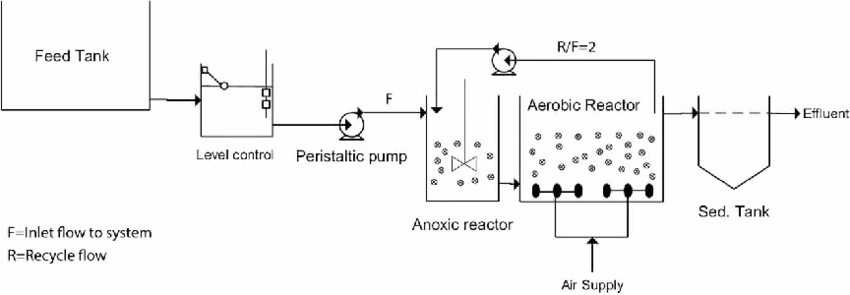

Tired of bulky wastewater treatment plants and murky discharge? MBRs offer a solution! These innovative systems combine powerful biological treatment with ultra-fine filtration, resulting in crystal-clear water, saving space, and adapting to various needs. While requiring upfront investment, MBRs ultimately deliver superior water quality and operational efficiency.